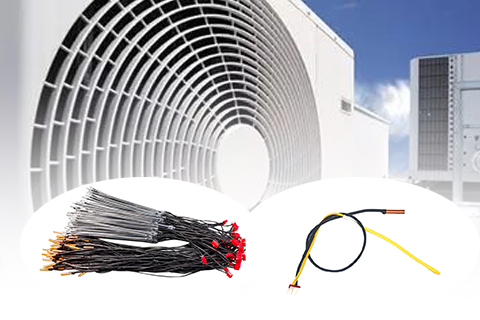

An AC temperature sensor is the core electronic component in air conditioning systems for precisely monitoring temperature changes, acting as the system’s “sensory nerves.” It detects real-time temperatures at critical points and feeds data to the AC control board, enabling intelligent regulation of cooling/heating operations to ensure efficient, safe, and comfortable performance.

Core Functions

Temperature Monitoring

Tracks temperatures of air, evaporator/condenser tubes, compressor, and other key components.

System Control

Sends temperature data to the control board to trigger compressor on/off cycles, adjust fan speed (inverter ACs), and activate defrost mode (heat pumps).

Safety Protection

Prevents evaporator freezing (low-temp protection) and compressor overheating (high-temp protection).

Key Installation Locations & Functions

| Location | Sensor Type | Primary Function |

|---|---|---|

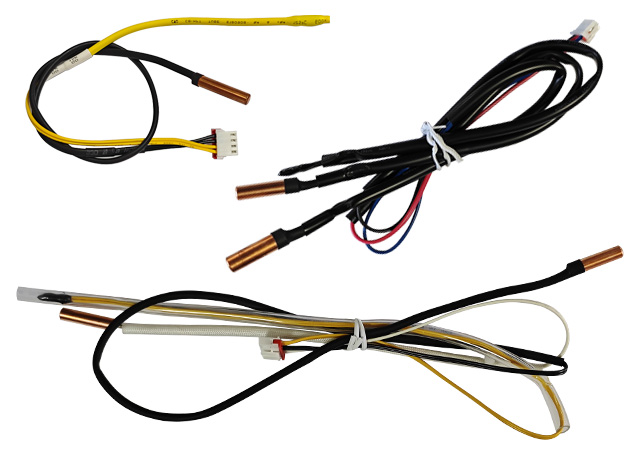

| Indoor Evaporator Coil | Tube Temperature Sensor | Monitors coil surface temperature; prevents icing (shuts down if <0°C); optimizes dehumidification |

| Return Air Duct | Air Temperature Sensor | Measures indoor air temperature; corrects thermostat inaccuracies (e.g., due to poor placement) |

| Thermostat/Controller | Room Temperature Sensor | Detects ambient temperature; primary trigger for AC start/stop cycles |

| Compressor Discharge Line | High-Temp Protection Sensor | Monitors outlet temperature (>130°C emergency shutdown; prevents compressor burnout) |

| Outdoor Unit | Ambient Temperature Sensor | Detects outdoor temperature; optimizes defrost logic; auto-switches cooling/heating modes |

| Condenser (Outdoor) | Tube Sensor (Commercial) | Controls condenser fan speed; improves energy efficiency |

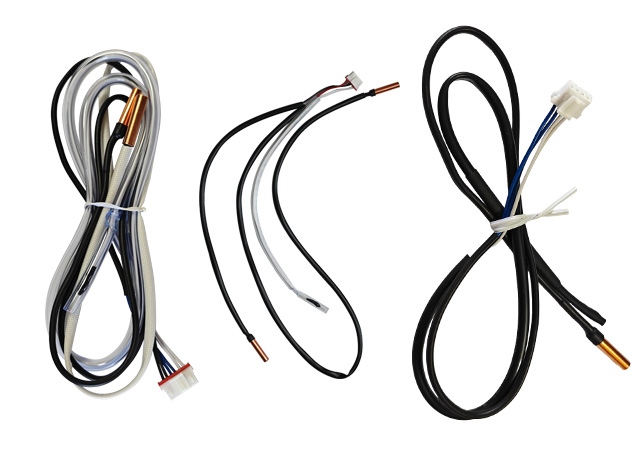

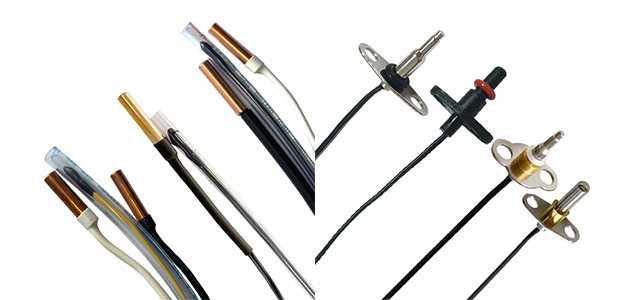

Common Temperature Probes: Types & Features

AC systems primarily use two probe types with distinct working principles:

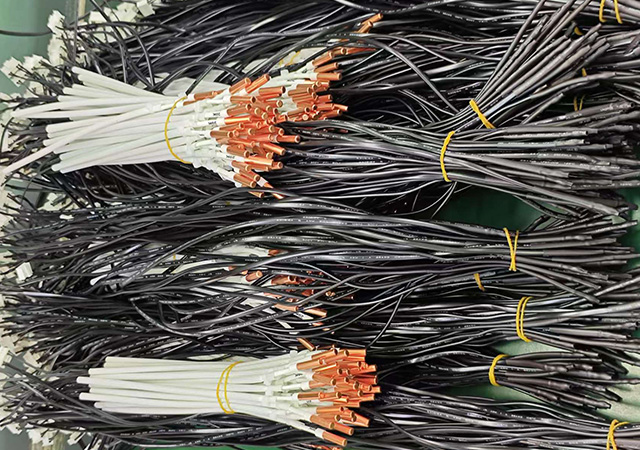

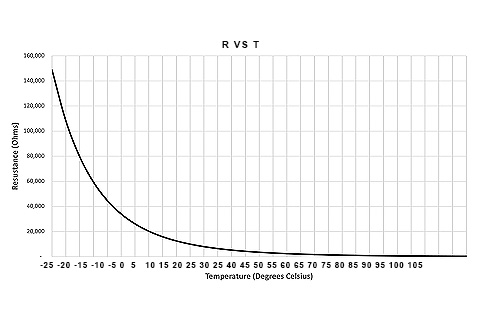

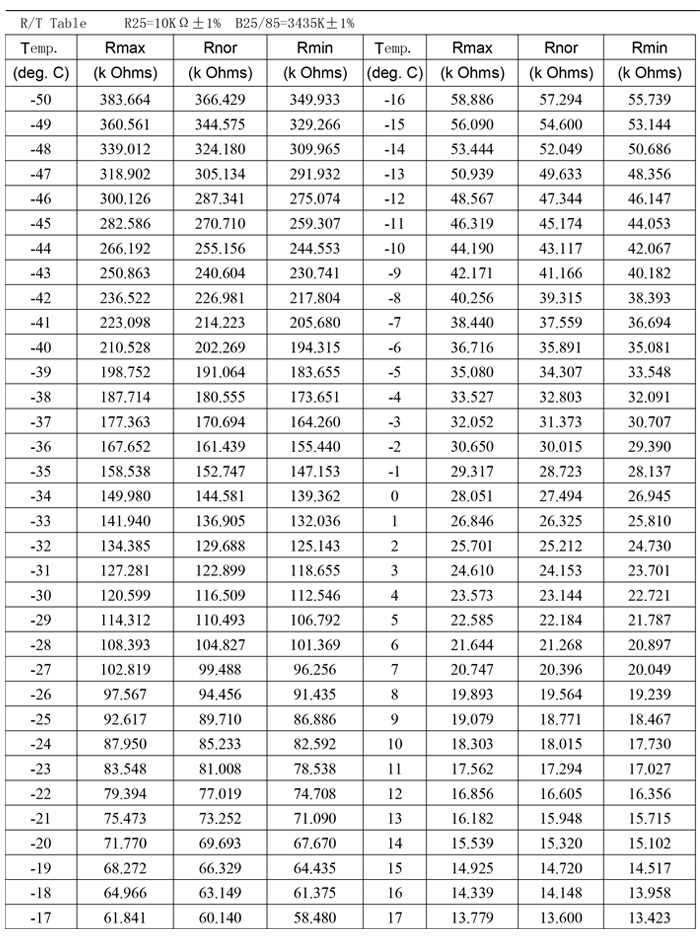

1. Thermistor (NTC Type)

Principle: Resistance decreases as temperature rises (Negative Temperature Coefficient).

Advantages: High sensitivity, fast response, low cost; ideal for AC operating range (-40°C~120°C).

Usage: >90% of AC sensors (evaporator/condenser temp, room temp, compressor protection).

2. Thermocouple

Principle: Generates voltage from temperature differences between two metal junctions.

Advantages: Withstands extreme heat (up to 1000°C); durable construction.

Limitations: Lower accuracy; requires cold junction compensation circuits.

Usage: High-temp zones (e.g., commercial compressor outlets); industrial HVAC systems.

Failure Impact: Symptoms of Sensor Malfunction

Faulty evaporator sensor → Frequent system shutdowns/coil icing

Failed room temp sensor → Erratic temperature control (continuous cooling/no startup)

Compressor sensor failure → No overheating protection; compressor burnout

Though small, AC temperature sensors are the silent commanders of efficient system operation. From freeze protection to energy optimization, they rely on precise temperature feedback. Regular maintenance—like cleaning air filters (to prevent false low-temp readings) and avoiding physical damage—extends your AC’s lifespan. Next time you enjoy cool comfort, remember these hidden “temperature sentinels”!